A decanter centrifuge is a highly efficient piece of centrifuge equipment. Decanter centrifuges are generally divided into two types: horizontal spiral filter centrifuges and horizontal spiral sedimentation centrifuges. Some users, however, have reported encountering issues with slow dehydration performance during operation. The specific problem involves an increase in the amount of material accumulating in the drum, which results in prolonged dehydration times and insufficient drying. This phenomenon is not uncommon, and in this article, I will analyze and attribute the possible causes of this issue. Continue reading

Monthly Archives: December 2024

GN 3-Phase Centrifuge Ready To Serve Oilve Oil Waste Treatemt

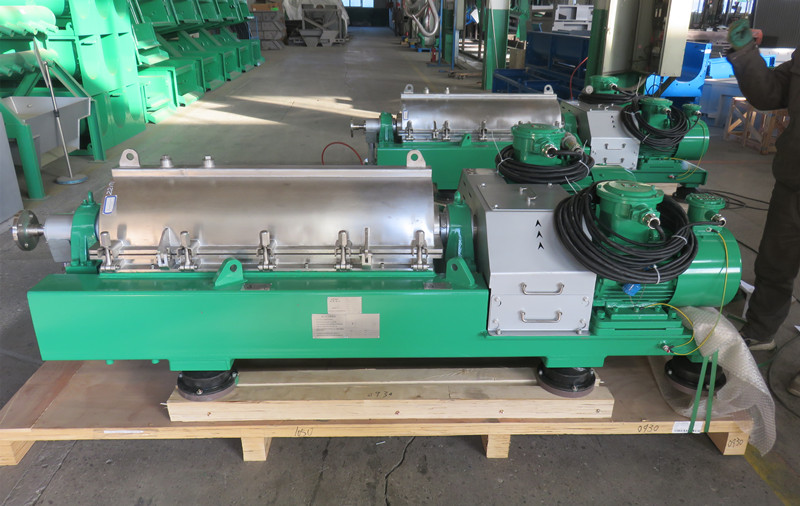

Recently, GN Separation completed the manufacturing and testing of two GNLWS554 Three-Phase Decanter Centrifuges. These centrifuges have been sent to North Africa to recover oil from olive oil sludge, a byproduct of production.

How GN 3-phase Decanter Centrifuge Operate

GN 3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 10 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

They are advanced machines used to separate mixtures into solids, light liquid (often oil), and heavy liquid (like water). The process starts by introducing the mixture into a rapidly rotating centrifuge bowl. The centrifugal force separates the components, pushing the heavier ones to the bowl’s wall and the lighter liquid to the center. A scroll propeller moves the settled solids to the discharge end, preventing re-mixing. Meanwhile, the light and heavy liquids are discharged separately from different outlets.

Application in Olive Oil Production and Sludge Treatment

Olive oil production creates large amounts of waste sludge with reusable oil. Traditional disposal methods are harmful to the environment and waste resources. The GNLWS554 centrifuges provide a sustainable solution by effectively separating the oil from the sludge, enabling its recovery for reuse in production or other applications.

Key Features of GNLWS554 Centrifuge

GN Separation’s GNLWS554 3-phase decanter centrifuges are designed robustly and are well-suited for challenging applications such as olive oil sludge treatment. Key features include duplex stainless steel for high corrosion resistance in handling oil-laden sludge, a centrifugal casting process for reducing vibrations and wear, and a centripetal pump design for fine-tuning the separation process and achieving consistent separation efficiency. These attributes make the centrifuges reliable and effective in environments where downtime is costly.

In summary, GN Separation’s 3-phase decanter centrifuges utilize advanced materials and innovative technologies to efficiently recover valuable oil from waste sludge. For further details, please feel free tocontact GN.

Decanter Centrifuge-Critical Tool for Efficient Separation

Introduction

In the dynamic world of oil and gas exploration and production, the centrifuge stands out as a critical tool for efficient separation processes. This versatile machine is employed to separate various components of drilling fluids, cuttings, and produced fluids, ensuring the smooth operation of oilfield activities.

Oil and Gas Application

The primary application of centrifuges in the oil and gas sector is the removal of solids from drilling mud. Drilling mud, or drilling fluid, is essential for lubricating the drill bit, controlling pressure, and carrying cuttings to the surface. Centrifuges help in maintaining the mud’s properties by efficiently removing the unwanted solids, thus extending the mud’s life and reducing the need for frequent replacements.

Water Treatment

Moreover, centrifuges play a vital role in the process of produced water treatment. Produced water, which accompanies oil and gas during extraction, needs to be treated before it can be disposed of or reused. The centrifuge’s ability to separate oil, water, and solids makes it an indispensable part of the produced water treatment process, helping to meet environmental regulations and reduce operational costs.

In addition to these applications, centrifuges are also used in the separation of hydrocarbons from water and the dewatering of hydrocarbon streams. These processes are essential for the quality control and preparation of products for transport and sale.

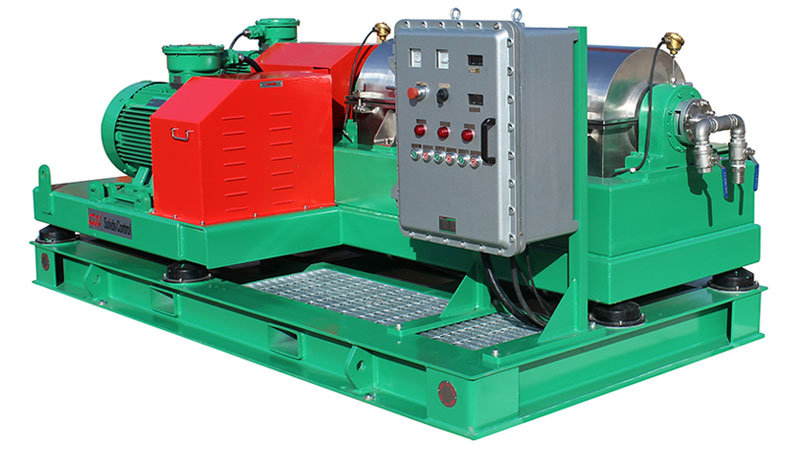

About GN Decanter Centrifuge

The full name of the decanter centrifuge is the horizontal screw decanter centrifuge, which is a widely used equipment in the field of industrial solid-liquid separation. According to the characteristics of different materials in different industries, GN decanter centrifuge is divided into dewatering, separation, and clarifying decanter centrifuge. With centripetal pump technology, GN decanter centrifuge can also realize the 3-phase separation of liquid, liquid, and solids. GN decanter centrifuges are widely used in the industry, and the products are exported to more than 60 countries and regions in the world, and have won high praise from customers.

How to extend the lifespan of Decanter centrifuge?

Just like people, objects require regular maintenance, especially precision instruments that demand meticulous care. Proper maintenance of a decanter centrifuge not only improves its performance but can also extend its service life by three to five years. Experts emphasize that those responsible for maintaining decanter centrifuges must pay close attention to the following important aspects to ensure their longevity:

GN NEW SEPARATION EQUIPMENT SHOWROOM HAS OPENED

GN Separation has officially opened its new equipment showroom, marking a key milestone in the development of its new factory. This state-of-the-art facility reflects the company’s dedication to innovation and technological progress, offering visitors an engaging and informative experience that highlights GN Separation’s operations and capabilities.

The showroom is organized into several distinct modules, each providing a detailed overview of GN Separation’s history, industry applications, and cutting-edge separation equipment. These modules include an introduction to the company, a section on industry applications, and a comprehensive display of the company’s equipment.

In the Company Introduction section, visitors can trace the journey of GN Separation from its modest beginnings as a small workshop with just 1,400 square meters of outdoor processing space to its current position as a leading enterprise spanning 120 acres and employing around 300 people. Over 16 years, GN Separation has evolved into a well-established name in the industry, earning the prestigious “Key Little Giant Enterprise” title from Hebei Province. This recognition highlights the company’s commitment to innovation, research, and development, as well as its significant contributions to the industry and society. The company’s growth, despite numerous challenges, underscores its resilience and success.

The Industry Applications and Separation Equipment Display sections offer visitors insight into the wide range of industries served by GN Separation’s equipment. In the drilling mud solids control sector, the company provides a diverse range of solutions, including shale shakers, de-sanders, mud separation centrifuges, and complete mud recycling systems. These solutions are critical for applications in oil and gas drilling, horizontal directional drilling (HDD), and slurry separation in piling and tunnel boring machine (TBM) projects. GN Separation also caters to the wastewater treatment industry, with equipment like sludge dewatering centrifuges, sludge screw presses, and chemical dosing units. Additionally, the company offers advanced mining equipment, such as ore vibrating screening for classification and dewatering, as well as dewatering centrifuges for tailings slurry dewatering and drying.

The showroom serves as a testament to GN Separation’s commitment to producing high-quality, durable, and efficient equipment tailored to the needs of clients across various industries. Known for their robustness and environmental efficiency, GN Separation’s products are designed to enhance operational productivity while minimizing environmental impact. The company’s ongoing focus on continuous innovation ensures that its solutions remain at the forefront of technological advancements, addressing the ever-evolving challenges faced by its customers.

Looking ahead, GN Separation is excited to welcome visitors from around the world to its new showroom, where they can explore the company’s expertise and discuss potential collaboration opportunities. With a solid foundation built on innovation, quality, and customer service, GN Separation is poised for even greater achievements in the field of separation technology.

How To Recover Waste Oil Effectively

GN waste oil recovery decanter centrifuges are tailored to fulfill the separation needs of the waste oil processing sector. Waste oil typically contains oil, water, and solids, and GN Separation equipment provides efficient solutions for separating these three phases while maximizing oil recovery.

Waste Oil Recovery Treatment

The waste oil recovery and treatment process involves handling various types of waste oil, including:

- Solids, water, and oil found at the bottom of oil storage tanks.

- Oily residues and slop oils generated from oil refineries.

- Oil sludge lagoons containing a mixture of oil, water, and solids.

- Oil-water mixtures from ship ballasts, which are the spaces in a ship’s hull that are partially or completely filled with water to improve stability.

- Sludge treatment from API (American Petroleum Institute) oil-water separators, which are used to separate oil and water in industrial settings.

- Discarded lubricant oils and emulsions from various industries.

- Industrial oil/water and emulsion waste streams, which may contain a mix of hydrocarbons, water, and other contaminants.

Advantages of GN Waste Oil Recovery Centrifuge

- More sizes available: The centrifuge is available in various sizes with a large length/diameter ratio of 4.2:1 or greater, allowing for greater flexibility in handling different volumes and types of waste oil.

- High G force: With a G force of up to over 3000 G, the centrifuge can effectively separate oil, water, and solids, ensuring high separation efficiency and oil recovery.

- Two-phase or three-phase separation: The centrifuge can be configured as a two-phase or three-phase separation decanter, depending on the specific needs of the waste oil recovery process.

- Explosion-proof design: The nitrogen purged centrifuge is designed for explosion-proof operation, ensuring safety in hazardous environments.

- Corrosion-resistant materials: The duplex stainless steel bowl is resistant to corrosion, extending the lifespan of the centrifuge and reducing maintenance costs.

- Automated operation: The centrifuge is equipped with VFD control, HMI, and PLC for automated operation, reducing the need for manual intervention and improving process efficiency.

- Adjustable parameters: The bowl speed, differential speed, and pump capacity can be adjusted to optimize the separation process for different types of waste oil.

- Wear protection: Various scroll and bowl wear protection systems made of tungsten carbide materials ensure the durability of the centrifuge and reduce the need for frequent repairs.

- Customized design: The centrifuge can be customized according to clients’ requirements, allowing for greater flexibility in meeting specific process needs.

- Global support: With worldwide partners and branches, GN offers fast support for waste oil recovery processes, ensuring that clients can rely on reliable and efficient service.

How to distinguish the quality of the decanter centrifuge

The environment of the manufacturers producing fake and inferior decanter centrifuge is extremely irregular, resulting in poor manufacturing process and product quality. This situation can be seen from the manufacturing process of the decanter centrifuge. Continue reading

GN Hydraulic Drive Decanter Centrifuge Utilized In Overseas Starch Production Project

Introduction

GN Separation has recently finished hydraulic drive decanter centrifuge, which will be crucial for a major starch production project located overseas.

The Importance of Hydraulic Centrifuges in Starch Production

Hydraulic centrifuges are indispensable in the starch production process, as they facilitate the efficient separation of starch granules from the slurry resulting from wet milling. This separation step is crucial for ensuring the purity and high quality of the final starch product, which is vital for diverse applications across the food, textile, pharmaceutical, and bioenergy industries. By utilizing the centrifugal forces generated by the machine, hydraulic centrifuges effectively eliminate impurities, fibers, and other unwanted substances, yielding a refined starch product that is ready for subsequent processing or immediate use.

GN Centrifuge Solution Tailored for Starch Production

GN’s hydraulic centrifuge, specifically designed for starch production, meets the stringent demands of the food industry. Here are the key features of this equipment:

- Food-Grade Safety with Polished Surfaces: Recognizing the significance of hygiene and product purity, GN’s centrifuge undergoes a polishing process on both the inner surface of the centrifuge bowl and the pushing screw propeller. This finish prevents material residue, ensuring that each batch of starch produced meets the highest food-grade quality standards.

- Internationally Renowned Hydraulic System: The precision machinery is powered by a reliable and precise hydraulic system from Swiss brand Viscotherm. This system includes a hydraulic differential for smooth operation and an efficient air-cooling system to maintain optimal temperatures during extended use.

- Advanced Monitoring and Safety Features: GN’s hydraulic drive centrifuge is equipped with a range of intelligent sensors, including automatic lubrication systems, temperature sensors, and vibration sensors. These features work together to detect and address any potential issues, ensuring safe and continuous operation of the equipment.

- Hygiene-Compliant Control Cabinet: Designed with the food industry’s hygiene requirements in mind, the control cabinet is made of corrosion-resistant stainless steel and is easy to clean. It is equipped with VFD (Variable Frequency Drive) and PLC (Programmable Logic Controller) overload protection, enhancing operational safety and extending the equipment’s lifespan.