In today’s globalized energy market, Africa, with its abundant oil resources, has gradually emerged as a crucial player on the global energy landscape. GN Solids Control, a renowned name in the industry, has successfully exported its advanced solids control system for oil well servicing rigs to African customers, marking a significant milestone in supporting Africa’s energy development journey.

I. Leading Technology from GN Solids Control, Adapting to Complex Environments

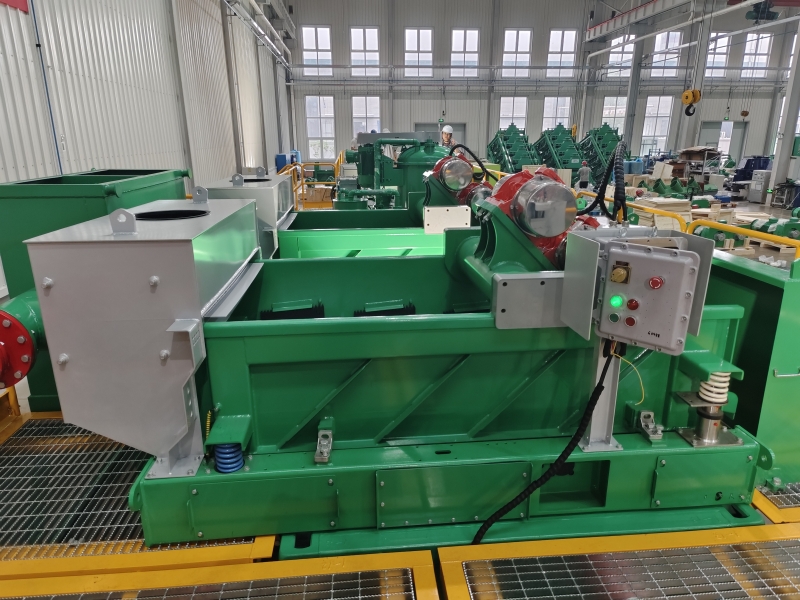

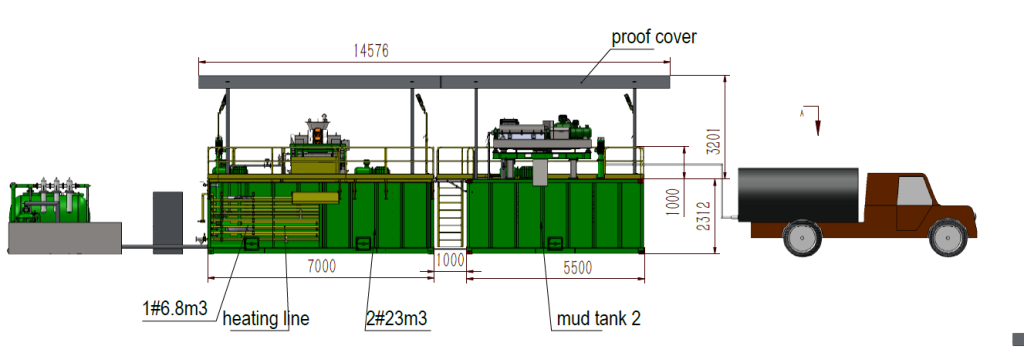

GN Solids Control, with its cutting-edge technology and vast experience, has designed a solids control system tailored to meet the unique challenges of Africa’s diverse and challenging geological conditions. The system efficiently processes the mud and solid particles generated during drilling operations, ensuring continuity and safety throughout the process. By integrating key equipment such as shale shakers, desanders, desilters, and centrifuges, GN Solids Control’s system delivers precise control and effective solid separation, thereby enhancing mud quality and reducing drilling costs.

II. Customized Solutions from GN Solids Control, Meeting Individualized Needs

Understanding the specific requirements of African customers and their local operating environments, GN Solids Control offers tailored solids control system solutions. From system configuration and process flow design to equipment selection, every aspect is carefully considered and optimized to seamlessly integrate into the customer’s existing operational system. This ensures efficient collaborative operations and maximum return on investment. Moreover, GN Solids Control provides comprehensive technical support and after-sales services, ensuring customers have peace of mind during the entire lifecycle of the system.

III. Environmental Awareness from GN Solids Control, Building Green Energy Dreams Together

At GN Solids Control, we recognize the importance of environmental protection amidst energy development. Our solids control system incorporates eco-friendly concepts from its inception, minimizing environmental impact through optimized processing technologies and the use of environmentally sound materials. We are committed to helping our customers establish green and sustainable energy development models, contributing to a cleaner and greener future for Africa and the world.

IV. Deepening Cooperation with GN Solids Control, Seeking Mutual Development

The successful export of GN Solids Control‘s oil well servicing rig solids control system to Africa is a testament to our strong technical capabilities, innovative spirit, and commitment to customer satisfaction. We view this as a new beginning in our journey of collaboration and mutual development with African customers. GN Solids Control will continue to leverage its expertise and resources to develop more advanced and customized solutions, supporting Africa’s energy development aspirations and contributing to the global energy industry’s growth.

Conclusion

With GN Solids Control’s advanced solids control system for oil well servicing rigs, we are empowering African customers with technology and building an energetic future together. We are proud to be a part of Africa’s energy development story and look forward to continuing our partnership with customers across the continent, driving progress and prosperity through innovative solutions.