Since the belt filter machine was the mainstream of sludge dewatering in sewage treatment plants in the past, the advantages of the centrifuge are shown in the treatment effect and comparison with the belt filter machine. The Decanter centrifuge has the following advantages for the belt filter machine:

①The Decanter centrifuge uses the principle of centrifugal sedimentation to separate the solid and liquid. Because the filter has a filter screen, it will not cause clogging. The belt machine uses the belt filter machine to separate the solid and liquid.

②The Decanter centrifuge is suitable for the concentration and dewatering of various types of sludge, and the belt filter machine is also suitable for various types of sludge, but the remaining activated sludge needs a large amount of medicine and the dehydration is difficult;

③When the feed concentration changes during the dehydration process of the Decanter centrifuge , the slip and torque of the drum and the screw will be automatically tracked and adjusted, so there is no need for a special person to operate, and when the feed concentration changes during the dehydration process, the belt filter machine speed, belt tension, dosing amount and flushing water pressure all need to be adjusted, and the operation requirements are high;

④In the Decanter centrifuge, fine sludge can also be separated from water, so the dosage of flocculant is small. Generally, the dosage of mixed sludge during dewatering is: 1.2kg / t [dry sludge], sludge recovery The rate is above 95%, the moisture content of the mud cake after dehydration is about 65% -75%, and the belt filter machine cannot be woven too densely because of the filter belt. In order to prevent the small sludge from leaking, more flocculant needs to be added In order to make the sludge form larger flocs, the dosage of mixed sludge during dehydration is generally greater than 3kg / L [dry sludge], the sludge recovery rate is about 90%, and the moisture content of the sludge cake after dehydration is about 80%;

⑤The power consumption per cubic meter of sludge dewatering of the centrifuge is 1.2kw / m3, the noise during operation is 76-80db, 24 hours a day continuous operation except the shutdown, no washing water is needed during operation; The power consumption is 0.8kw / m3, the noise during operation is 70-75db, the filter cloth needs to be relaxed and maintained. Generally only two shifts are arranged every day, and the filter cloth needs to be continuously washed with high-pressure water during operation;

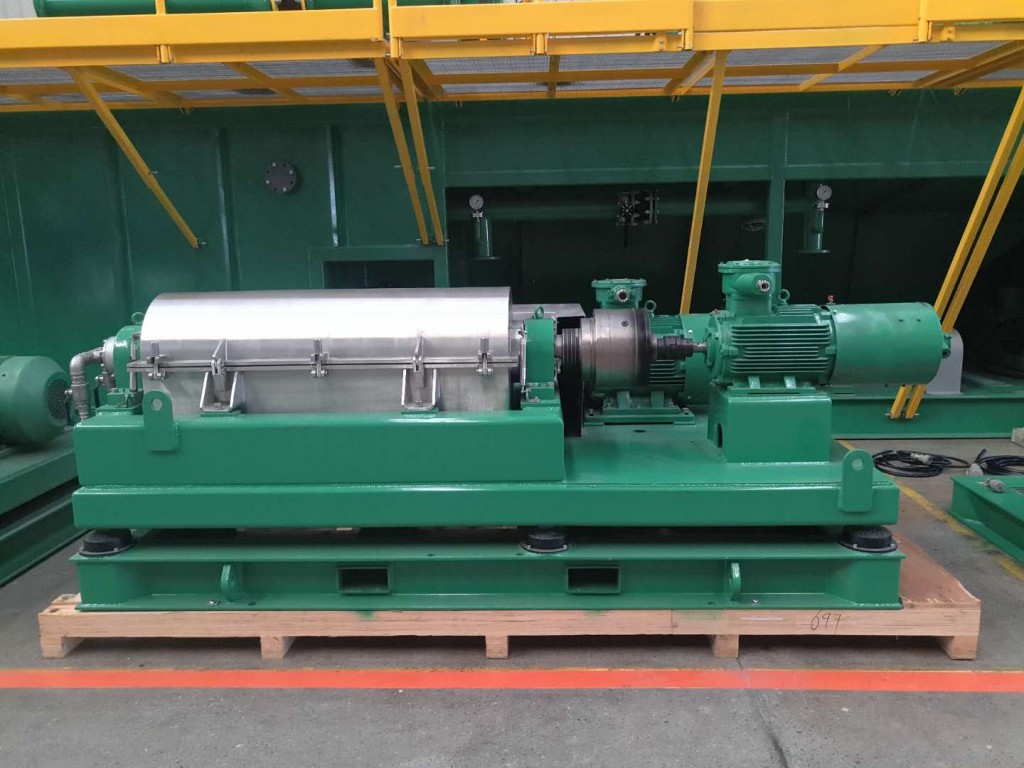

⑥The Decanter centrifuge takes up little space, the installation and commissioning are simple, the supporting equipment is only the dosing and feeding and discharging conveyors, the whole machine is fully sealed, and the workshop environment is good; while the belt machine covers a large area, the supporting equipment is not only dosing and feeding and discharging Outside the machine, a flushing pump, air compressor, sludge conditioner, etc. are needed. The whole machine has poor sealing performance. High-pressure cleaning water mist and odor pollute the environment. If the management is not good, it will cause mud overflow;

⑦ The wearing parts of centrifuges are bearings and seals, and the maintenance cycle of the discharge screw is generally more than 3a; while the wearing parts of the machine, in addition to bearings and seals, the belt filter machine also needs to be replaced, which is expensive